Our modern manufacturing facility has implemented a quality control system that meets the requirements laid down in HACCP (Hazard Analysis and Critical Control Points), good manufacturing practice (GMP) and good hygienic practice (GHP). Our company is under constant supervision of the Main Sanitary Inspectorate and meets all legal and quality requirements related to manufacturing process and placement of food and dietary supplements on the market.

![]()

The issue of quality is very important to us. That is why we apply the GMP principles at every stage of production. This is the core of our business, which is conducive to our success. As a contract producer we have direct impact on the commercial success of our clients. This is an enormous responsibility, so we treat quality control of our diet supplements very seriously, exactly as if we were producing them for ourselves. We do not make allowances for any incompatibilities and take full responsibility for the quality, stability and safety of products delivered to customers.

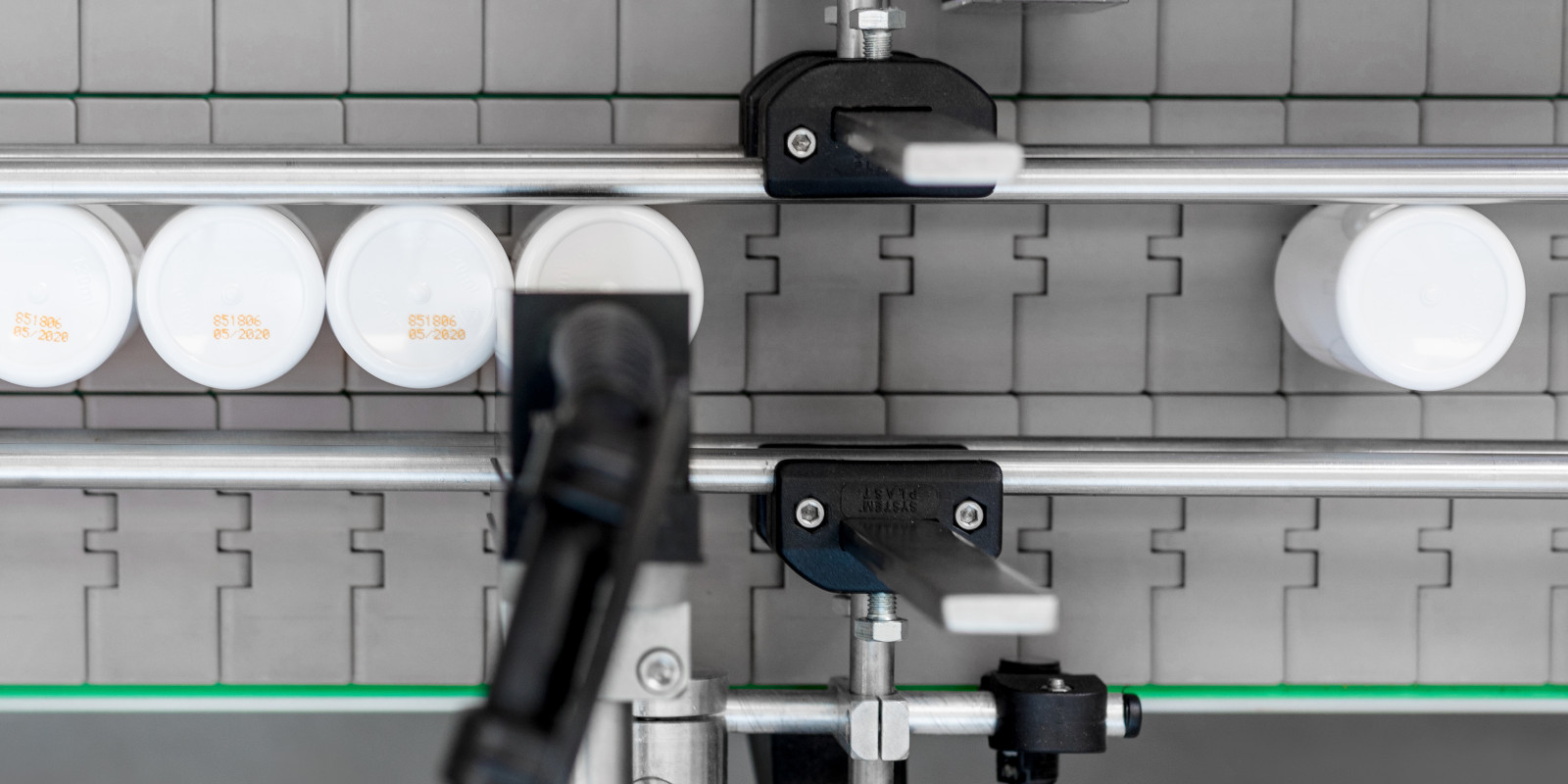

Quality assurance is not just an empty slogan and we do not treat it as a legal obligation to control manufactured supplements before sale. Their production should be treated in a comprehensive manner already at the design stage of the entire technological process sequence. Only in this way are we able to eliminate all potential errors and reduce the risk of non-compliance. Every stage is very important, starting from acceptance and control of input materials, through weighing and mixing of ingredients, transfer of intermediate products in the manufacturing department, packaging process, and ending with the release of finished products from the warehouse. This comprehensive approach is known as Quality Control by Design (QCBD). And all this is undertaken to ensure that each product leaving our factory is fully compliant with the specification and safe.

Owing to this fact, clients of SUPPLELAB may be sure that supplements received by them are not the result of an accidental formulation but a carefully designed composition. They are manufactured with exceptional attention paid to the smallest details. The history of each packaging can be traced using the lot number which will lead us to manufacturing parameters registered, raw materials used, their exact specification and results of laboratory tests on the basis of which it was released for sale.

Control of all technological processes in your own plant is a matter of optimal organization of work and continuous improvement. There are however factors directly affecting the quality of the product that result from work undertaken by other units. We refer here to raw materials – the basic ingredients of each supplement produced by SUPPLELAB.

We do not pay attention only to a price when choosing our suppliers. The quality of raw materials translates directly into the highest quality and safety of our supplements. Not everyone can become a supplier of SUPPLELAB. We cooperate only with reliable producers of the highest quality components from around the world. Despite careful selection of business partners, each raw material lot has to meet strict requirements defined by our experts before being released for production.

In cooperation with an external accredited laboratory, the quality department controls raw materials and finished products to check if the packaging contents is completely consistent with its labelling. The raw materials, intermediate products and finished products are subject to detailed analysis. This allows us to maintain full compliance with the specification in terms of purity, composition and all physicochemical parameters. Methods implemented to control quality in an ongoing manner allow us to maintain all the desired features of the product. They reduce threats to its stability not only directly after production, but also throughout the entire life cycle.

We attach enormous importance to the conditions under which our supplements are manufactured. We take care about the cleanliness of production rooms in which we constantly control temperature and humidity. Our employees adhere to strict hygiene rules, reducing the risk of direct contact with the product and its contamination. All operators follow strict detailed job instructions, while process documentation is subject to constant control through the implemented data flow system.

Customer feedback is our best recommendation. As a reliable business partner, SUPPLELAB has gained reputation of the manufacturer of the highest quality dietary supplements which is distinguished by innovativeness and uncompromised attention to every detail.